SKIP LOADER B.O.B.

The BOB skip loader range is designed and built according to your working necessities. The six skip loder models are available both with fixed and telescopic arms, from 8 ton to 18 ton capacity. The possibility of variants and options can customize the B.O.B. skip loaders according to your working necessities. Strength, duration and reliability are only some of the benefits deriving from the use of our skip loader handling system.

All BoB Hydraulic Systems multibenne handling systems can be equipped with the

exclusive BoB Connect system and

benefit from tax breaks in favor of technological investments related to the “Industry 4.0” program.

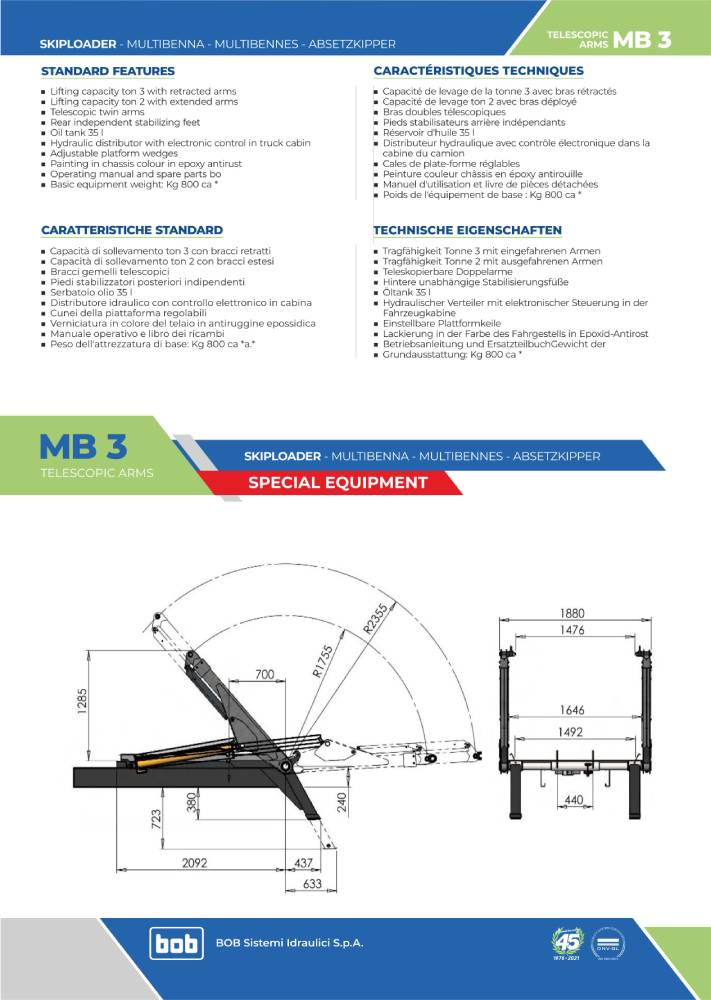

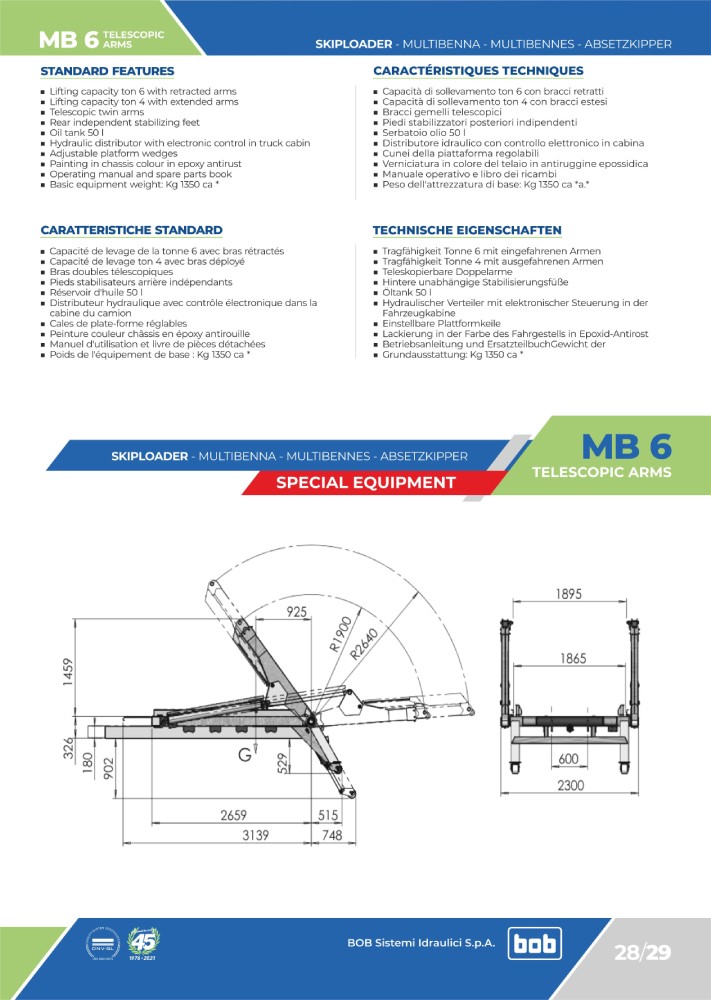

MAIN SPECIFICATIONS:

High weight-to-power ratio thanks to the use of high strength steel. The skip loaders from B.O.B. Sistemi Idraulici SpA are designed for heavy duty and high productivity granted over time.

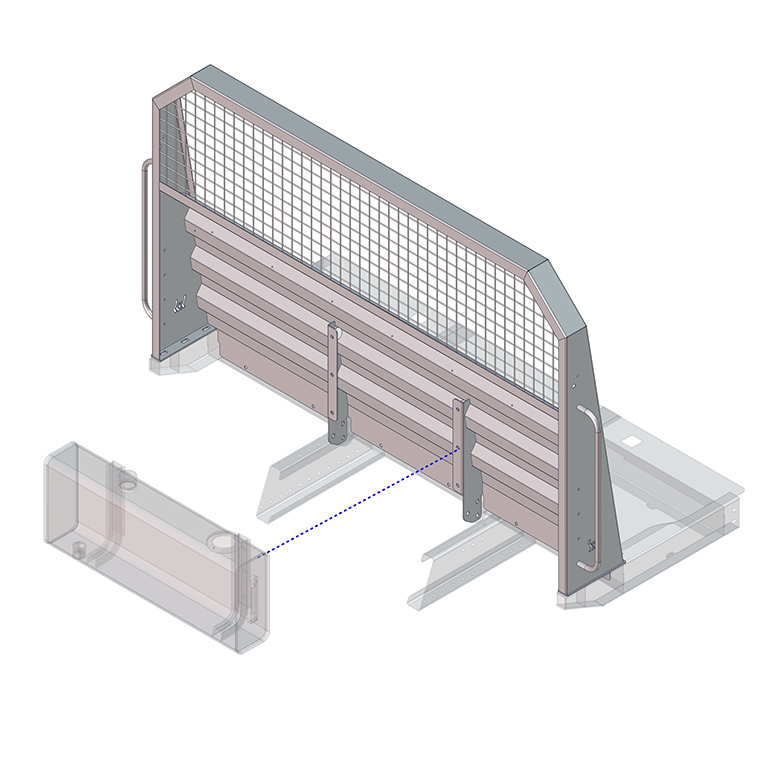

Starting from the model MB 8, the skip loaders from B.O.B. Sistemi Idraulici are designed according to a modular criterion. This allows to choose the front area configuration type: front type with compact oil tank without cab protection, front type with cab protection, front type with cab protection and compact oil tank. This system makes the dealer’s parts management easier, and at the same time it gives the possibility to customize the equipment.

Programable control box with spiral cable. The new B.O.B. SISTEMI IDRAULICI skip loaders’ control device is based on the CAN BUS technology. It interacts with the machineside control unit which also acts as a receiving unit. No further electrical and electronic components mounted, only a minimum of electrical wiring and watertight components are the best warranty of system reliability. BoB Easy C is installed as standard on the entire range of BoB hooklifts.

The new B.O.B. SISTEMI IDRAULICI skip loader’s control device is based on the CAN BUS technology. It interacts with the machineside control unit which also acts as a receiving unit. No further electrical and electronic components mounted, only a minimum of electrical wiring and watertight components are the best warranty of system reliability.

BoB Connect is a telediagnostic system with satellite interconnection specific for hooklifts, skip loaders, loading cranes and agricultural trailers. The system allows you to monitor the location and conditions of use of the equipment through a data network. BoB Connect allows you benefit from the tax relief provided to support technological investments related to the “Industry 4.0” program.

On all B.O.B. SISTEMI IDRAULICI skip loaders range there are mounted high-capacity hydraulic flow controls and components to increase the manoeuvers speed. This solution, together with the correct sizing of the hydraulic oil tank, keeps the oil operating temperature at the best level and protects the hydraulic components.

The oil cooler keeps the hydraulic oil operating temperature under control and protects the hydraulic components, maintaining the characteristics of the hydraulic oil. This accessory is particularly suitable for heavy duty work or when also other equipment is used.

An optional function, allowing the independent movement of the telescopic arms, is availabe to allow loading and unloading manoeuvers in the most difficult situations, even when the truck is not perfectly aligned with the container.

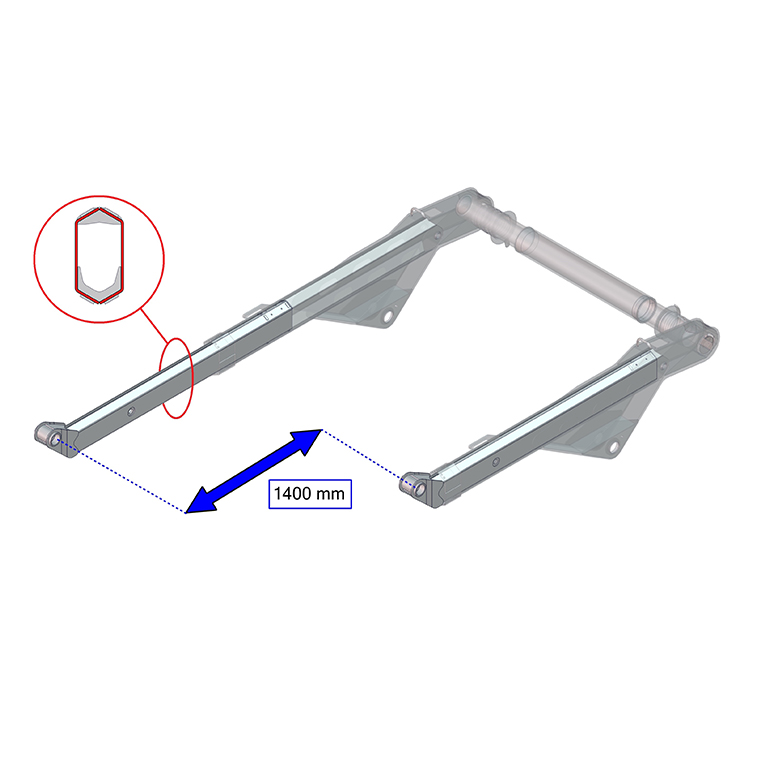

The MB 14, MB 16 and MB 18 models have a hexagonal arm profile with which unparalleled lifting capabilities are achieved, while keeping weights and measures lower than most other equipment.

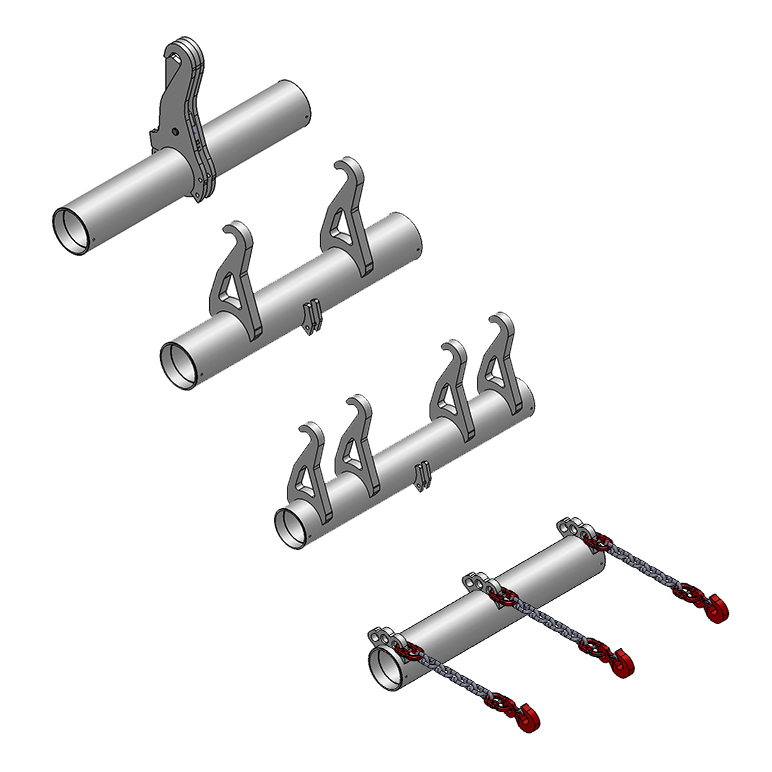

Tipping hooks available in four different versions to best adapt to work needs.

– bareno with chain tipping hooks for manual application

– bareno with fixed double tipping hook

– bareno with 4 fixed tipping hooks

– bareno with central fixed hook and tipping opening with safety

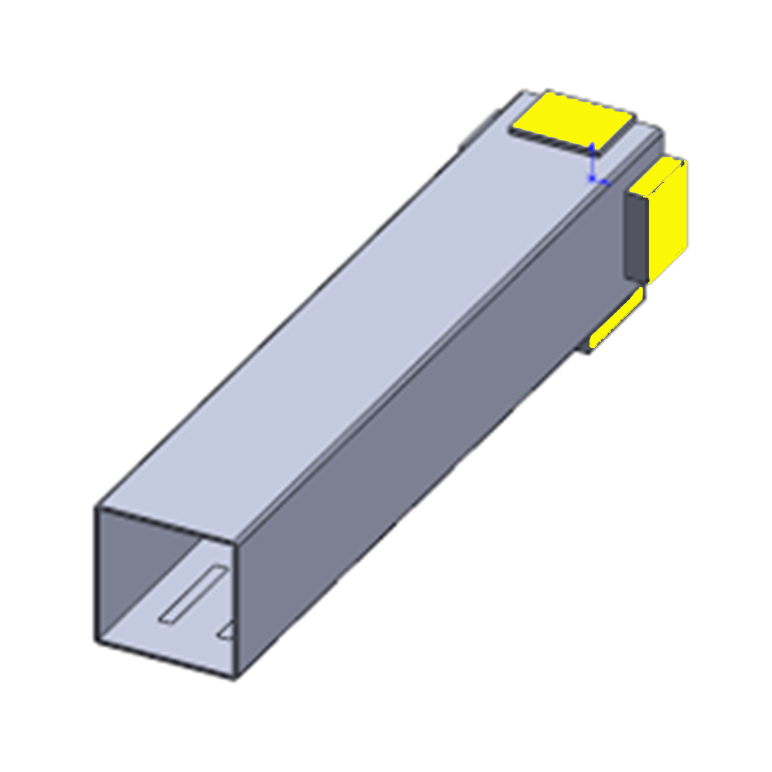

The telescopic cylinders are mounted inside the arm, while the hydraulic system, the flow control and the hydraulic pipes are totally protected by special protection cases made of carpentry.

– Certified chain and hook with chain eye

DIN certified chain and hook

– SK1 certified chain and hook