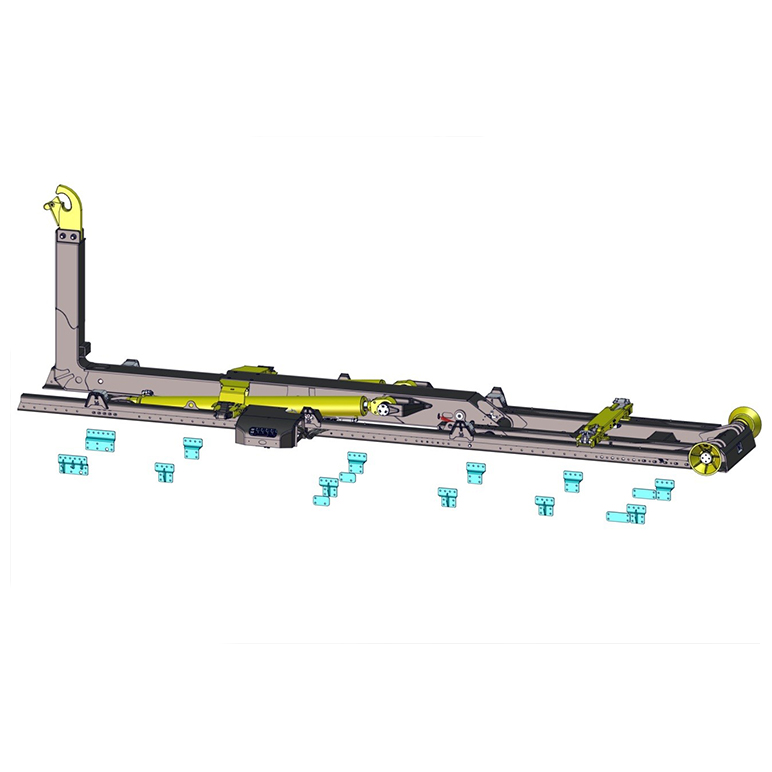

ARTICULATED AND TELESCOPIC ARM HOOKLIFTS – TA –

The BOB hooklift range is designed and built according to your necessities. With over 30 models of hooklifts available in more than 400 versions, we can configure your equipment to fit your needs perfectly. Strength, endurance and reliability are only some of the benefits deriving from the use of our container handling systems. Our customers can also count on an unmatched range of standard and optional features for any need.

All the hooklifts of the BoB Sistemi Idraulici range can be equipped with the exlucsive BoB Connect system and benefit from tax advantages in favor of technological investments linked to the “Industry 4.0” program.

MAIN SPECIFICATIONS:

High weight-to-power ratio thanks to the use of high strength steel. The hooklifts of BoB Sistemi Idraulici are designed for heavy duty work and high productivity guaranteed over time.

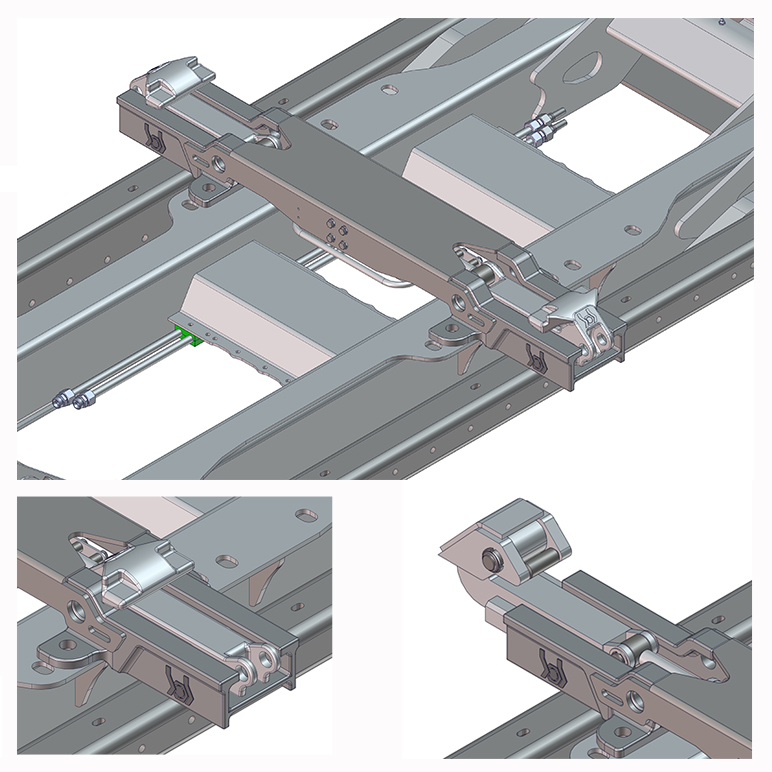

Pierced underframe The piercing of the longitudinal members allows the ideal positioning of the fixation plates, saving time during the mounting phase. No need to weld the fixation plates keeps the original features of the structural components.

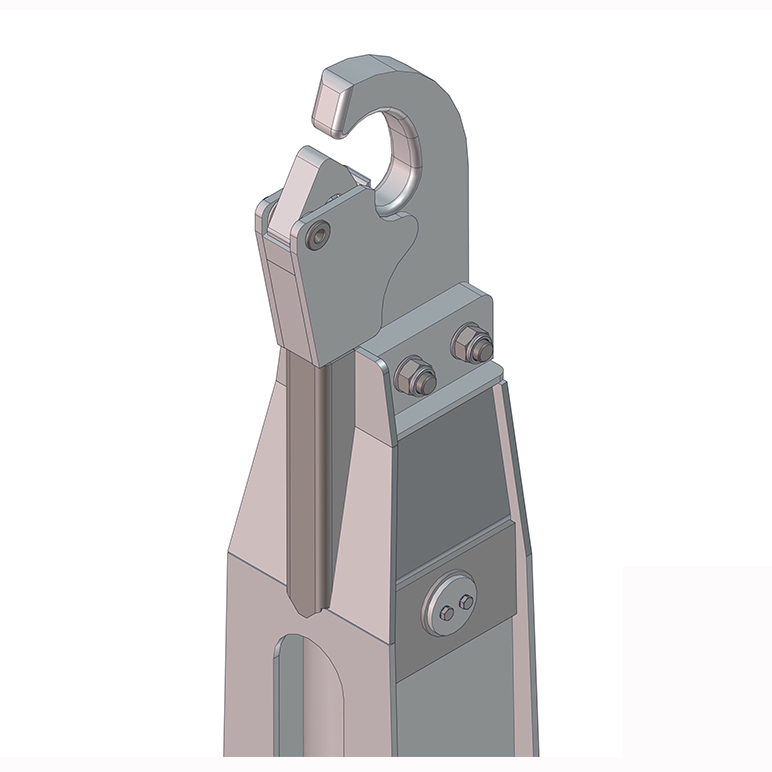

The bolted hook ensures easy and fast replacement in case of damage and the hook gravity system grants maximum safety during container loading / unloading operations.

Optional pneumatic hook locking device allows safety locking regardless of the angle and position of the main arm.

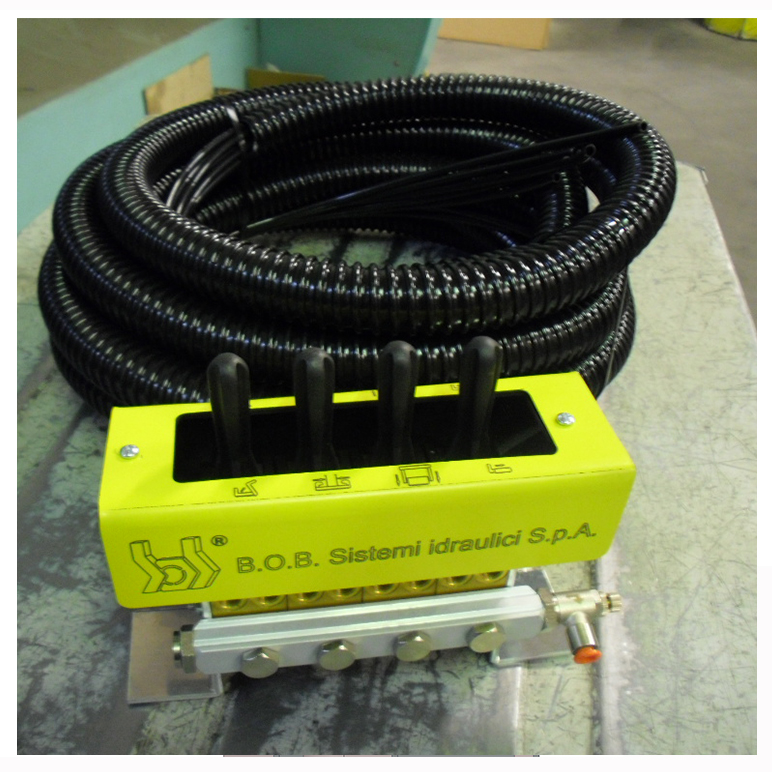

Programable control box with spiral cable. The new radio control for the hooklifts of B.O.B. Sistemi Idraulici is based on the CAN BUS technology and interfaces with the main equipment also acting as a receiver unit. No further electrical and electronic components mounted, only a minimum of electrical wiring and watertight components are the best warranty of system reliability. BoB Easy C is installed as standard on the entire range of BoB hooklifts.

The new optional radio control for the hooklifts of B.O.B. Sistemi Idraulici is based on the CAN BUS technology and interfaces with the main equipment also acting as a receiver unit. No further electrical and electronic components mounted, only a minimum of electrical wiring and watertight components are the best warranty of system reliability.

Pneumax pneumatic control with wired control in the cab.

BoB Connect is a telediagnostic system with satellite interconnection specific for hooklifts, skip loaders, loading cranes and agricultural trailers. The system allows you to monitor the location and conditions of use of the equipment through a data network. BoB Connect allows you benefit from the tax relief provided to support technological investments related to the “Industry 4.0” program.

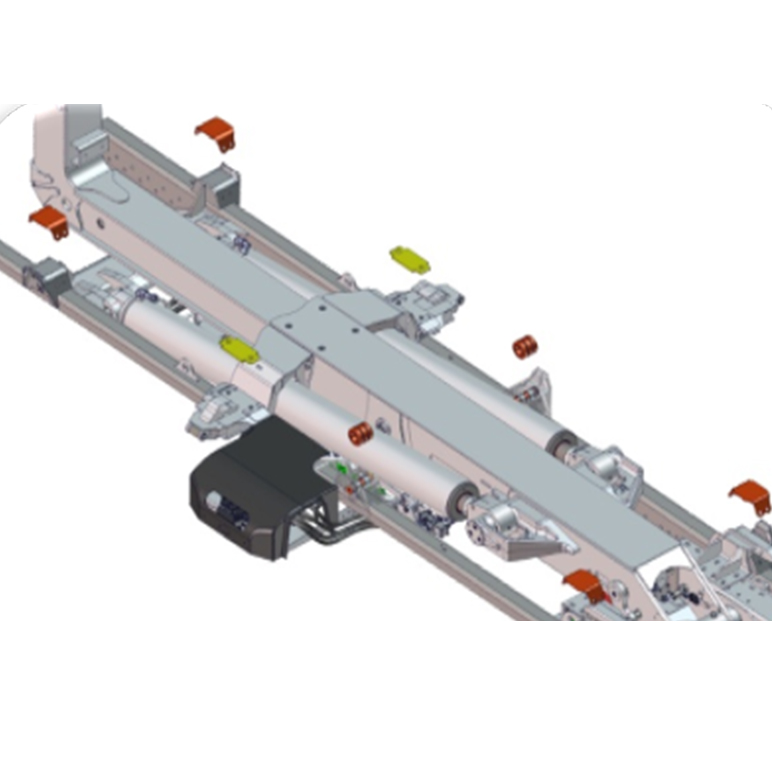

The lower part of the hooklift, including also the crossbar member of the lifting cylinders, allows the equipment mounting even in the presence of the gearbox above the chassis level for all-wheel-drive vehicles 4×4 6×6 8×8.

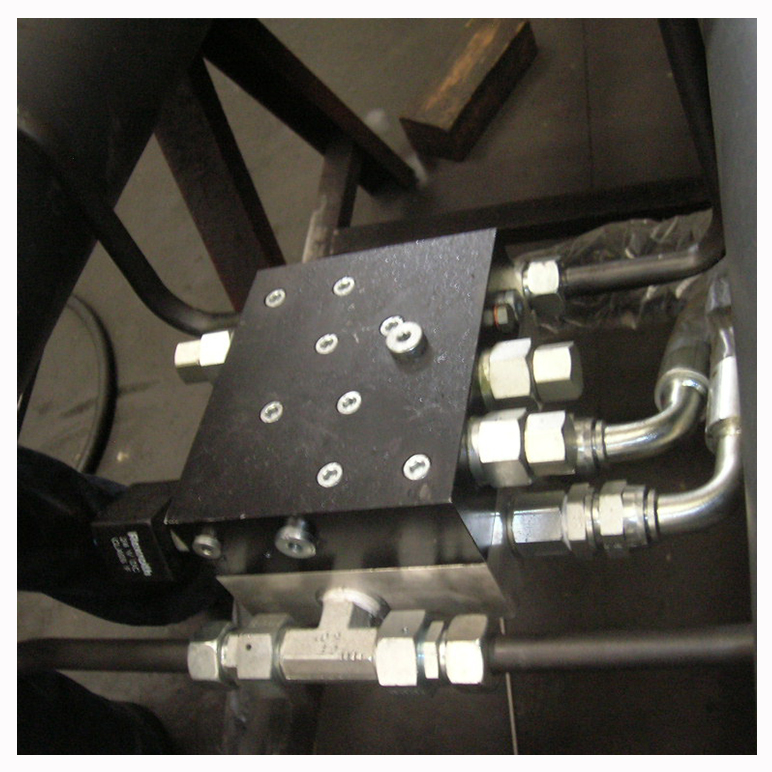

On the entire hooklift range of BoB Sistemi Idraulici there are mounted high capacity flow controls and hydraulic components to increase the manoeuvres speed. This solution, together with the correct sizing of the hydraulic oil tank, keeps the oil operating temperature at the best level and protects the hydraulic components.

The main structural components subject to handling such as pin seats, lifting jack supports, piston heads are made of cast steel. The molded steel components guarantee a longer life and a lower weight than the traditional components made of metal sheet.

Interchangeable galvanized container supports. This particular solution allows you to replace worn supports, restoring the original condition of the supports and guides in a very short intervention time.

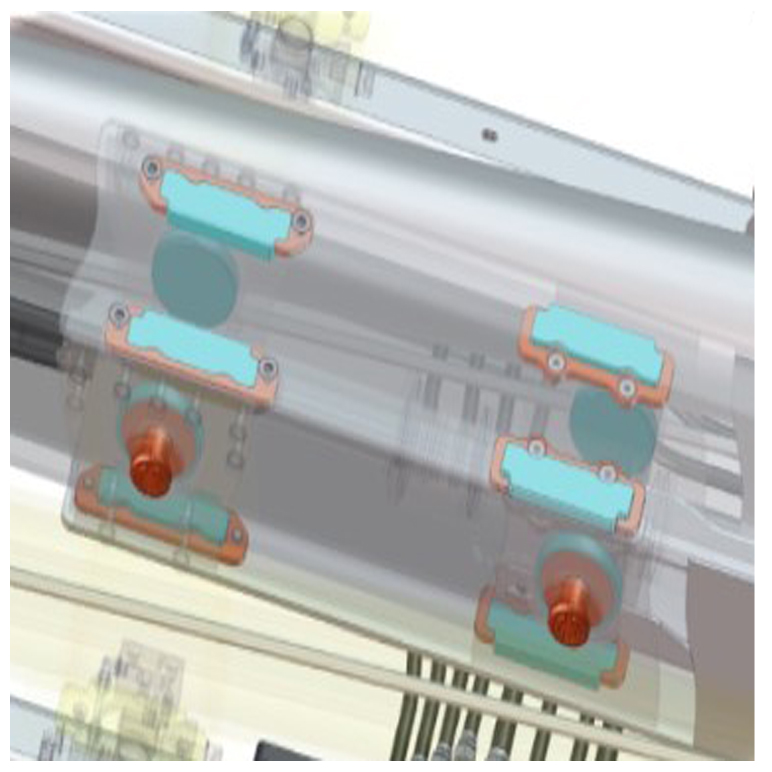

MODULAR sliding pads. This new construction concept of the central body allows you to adjust the sliding pads after a long period of use, bringing the arm back to its original working condition and reducing complex maintenance work.

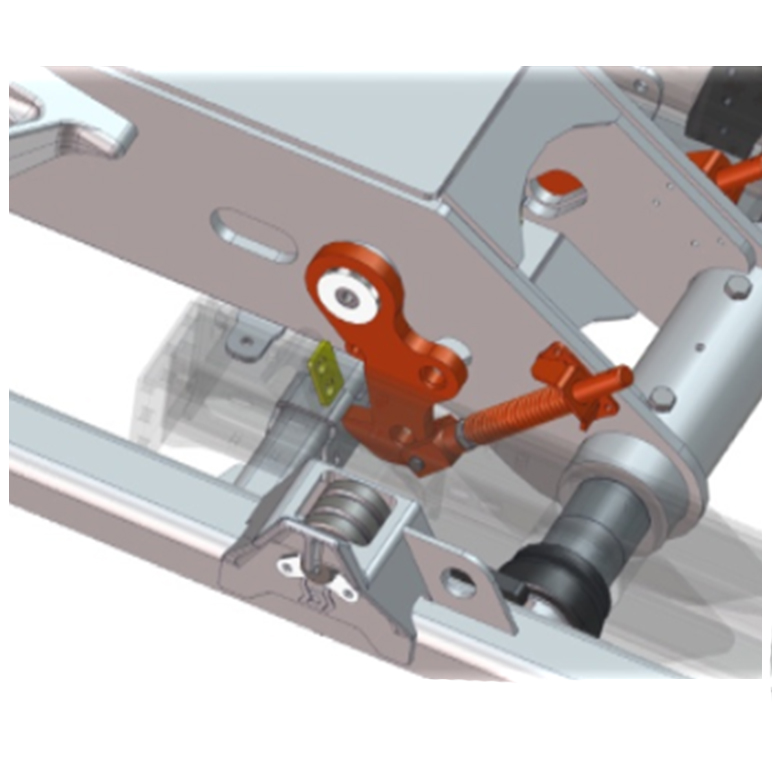

This mechanical safety device, completely independent of the telescopic arm operation, is inserted automatically during tipping and disengaged when the equipment returns from tipping to a resting position on the frame, ensuring maximum safety during the tipping phases.

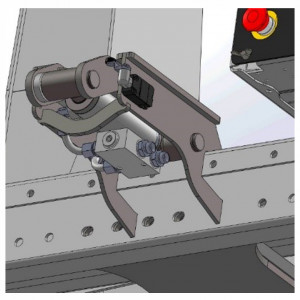

Standard case locking device (internal – external reversible type), DIN-compliant locking and CHEM-compliant locking

The front locking grants additional safety during the container transport. It is particularly suitable for vehicles that need to load machinery such as mini-diggers, mini-loaders etc. in the back of the container.

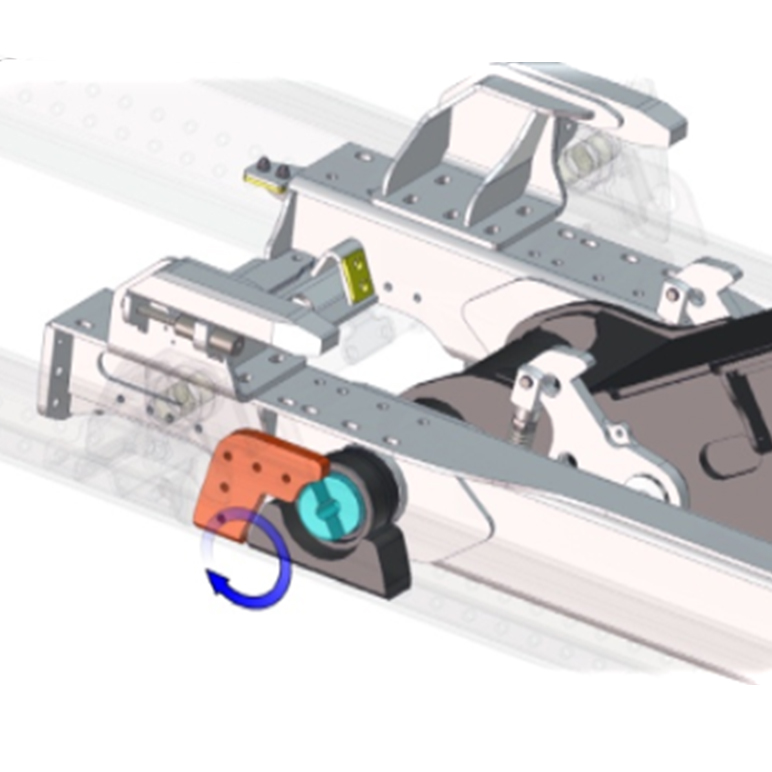

BoB hooklifts, starting with the T20 model, can be equipped with the optional front locking system MLS “Mobile Locking System” (patented) which is mounted on the lifting arm. This locking allows you to have a constant container locking during the tipping phase, maintaining a support on 4 points.

The oil cooler keeps the hydraulic oil operating temperature under control and protects the hydraulic components, maintaining the characteristics of the hydraulic oil. This accessory is particularly suitable for heavy duty work or when also other equipment is used.

The mechanical stop of the rear frame installed on the pierced longitudinal members is specific for the translation of the container from / to a hooklift trailer, ensuring full operational flexibility for telescopic arm maneuvers.