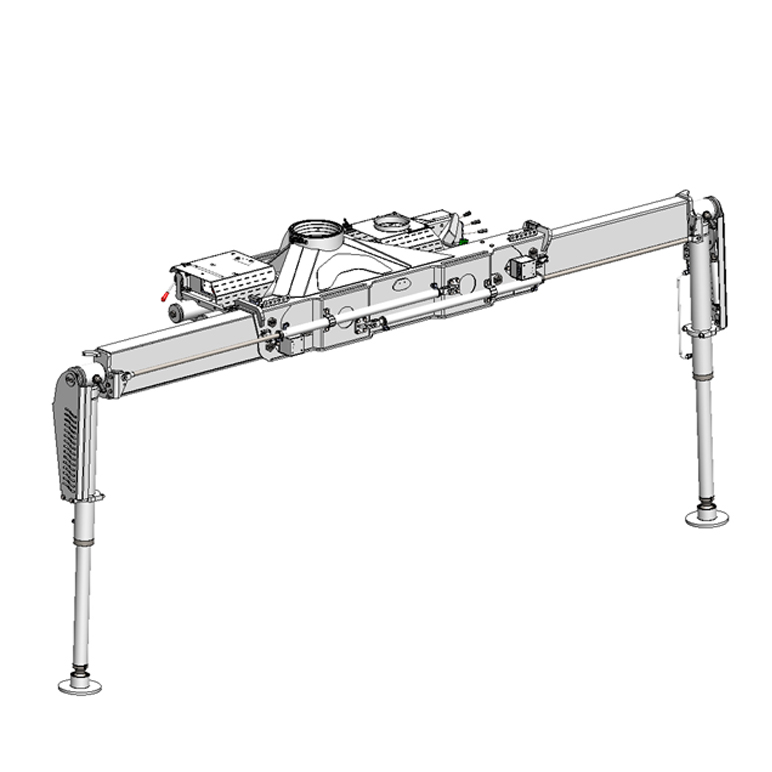

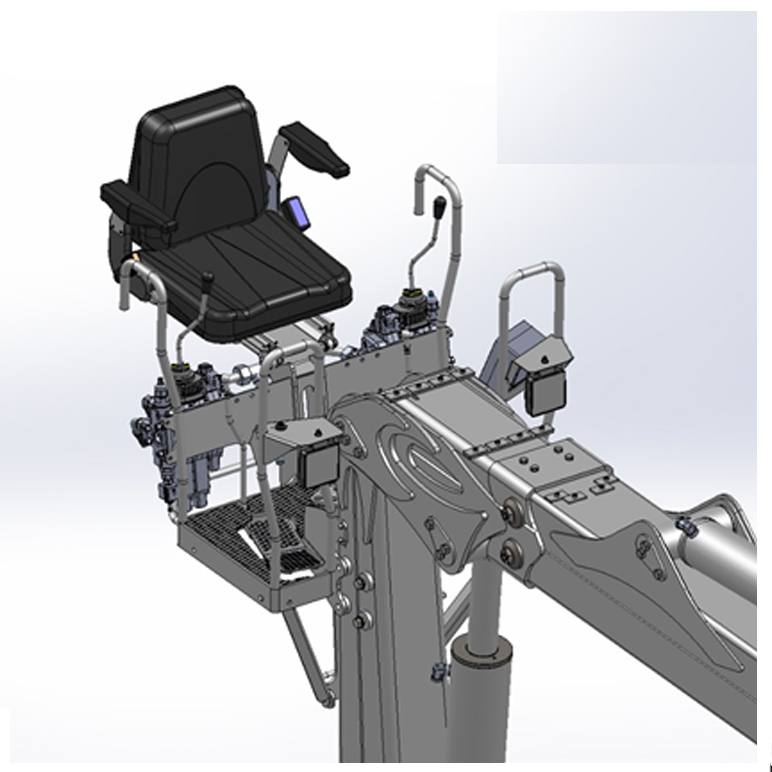

NON FOLDABLE LOADING CRANES BEHIND THE CAB – R

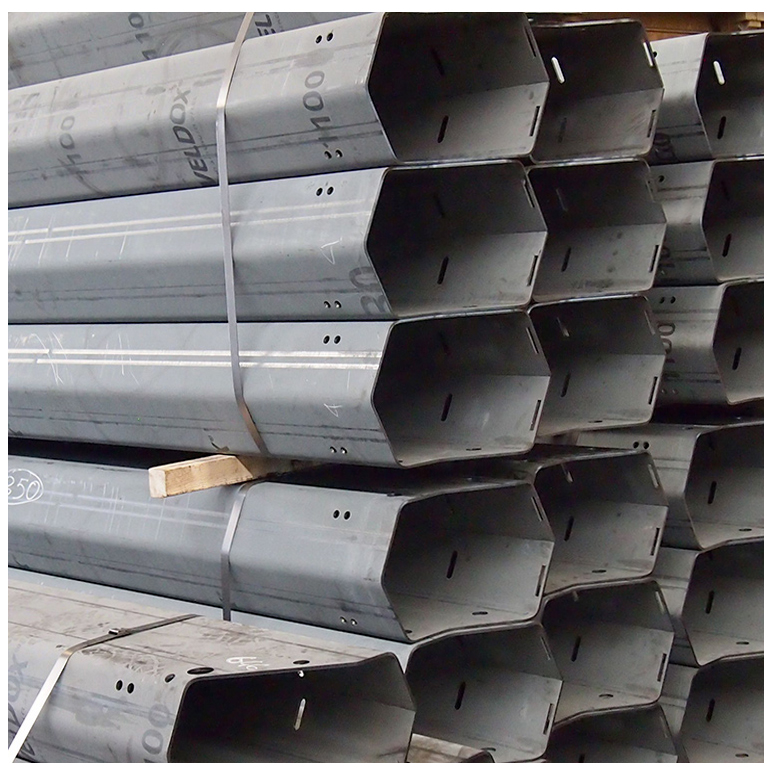

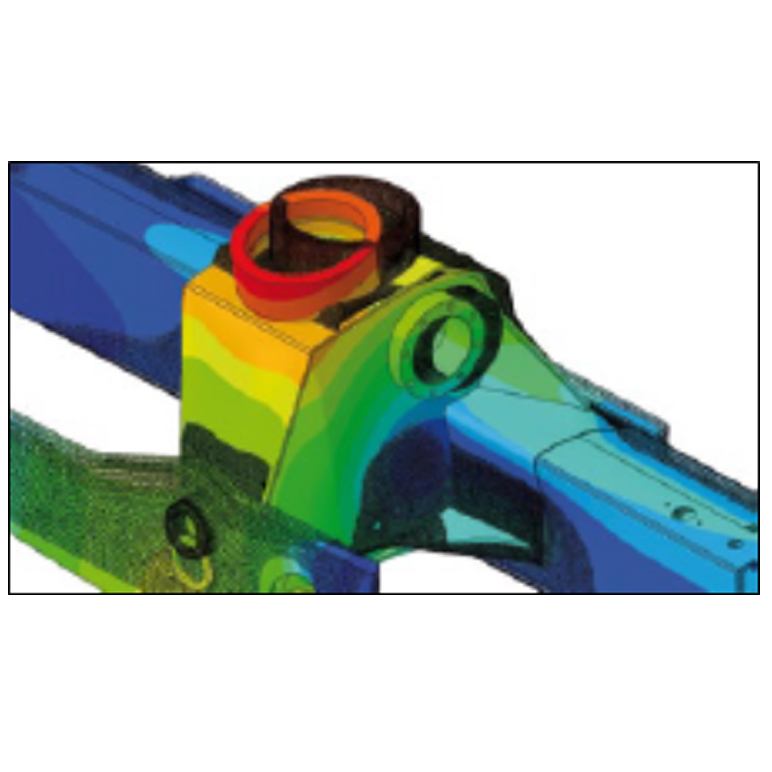

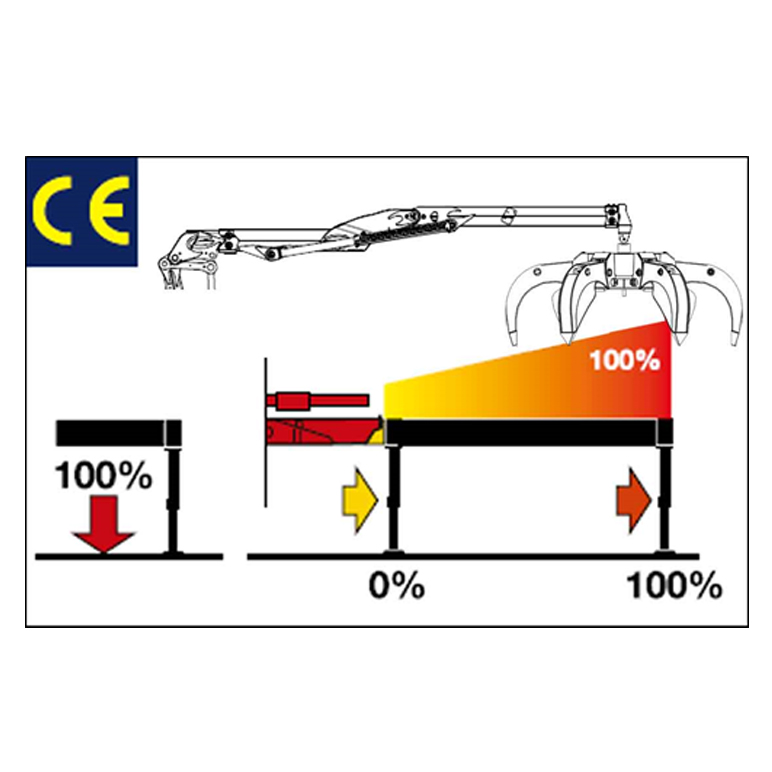

The BOB Italev loading cranes are designed to ensure the best performance in terms of lifting capacity, operational speed and reliability. The production of BOB Italev loading cranes from 11 tm to 15 tm covers the main needs in terms of lifting capacity required for different uses, timber handling, waste collection, ferrous materials and bulk building materials. The range covers both foldable loading cranes (W series) and non-foldable loading cranes (R series), each of them configurable with different boom types.

In 2019, the new REVO range was presented, making a big step forwards in the control of loading cranes movements. The production of the REVO range will begin in early 2021.

All BoB Italev loading cranes can be equipped with the exclusive BoB Connect system and benefit from tax breaks in favor of technological investments related to the “Industry 4.0” program.